This post is intended for people who're considering equipping their vehicle with air suspension. If you've purchased a camper/motorhome that already has air suspension but it didn't come with any instructions then our basic setup guide is AVAILABLE HERE.

Rear kit for leaf spring/AL-KO

Around 75% of all UK motorhomes are Fiat Ducato/Citroen Jumper and Relay/Peugeot Boxer based, followed by Mercedes Sprinter/VW Crafter and Ford Transit. We supply kits for all of them, and quite a few more too. In fact almost all UK sold vans, motorhomes or minibuses.

We supply kits for both AL-KO (2006+ vehicles) and leaf spring (1994+) chassis for Ducato/Jumper/Relay/Boxer motorhomes and leaf spring chassis kits for other motorhomes.

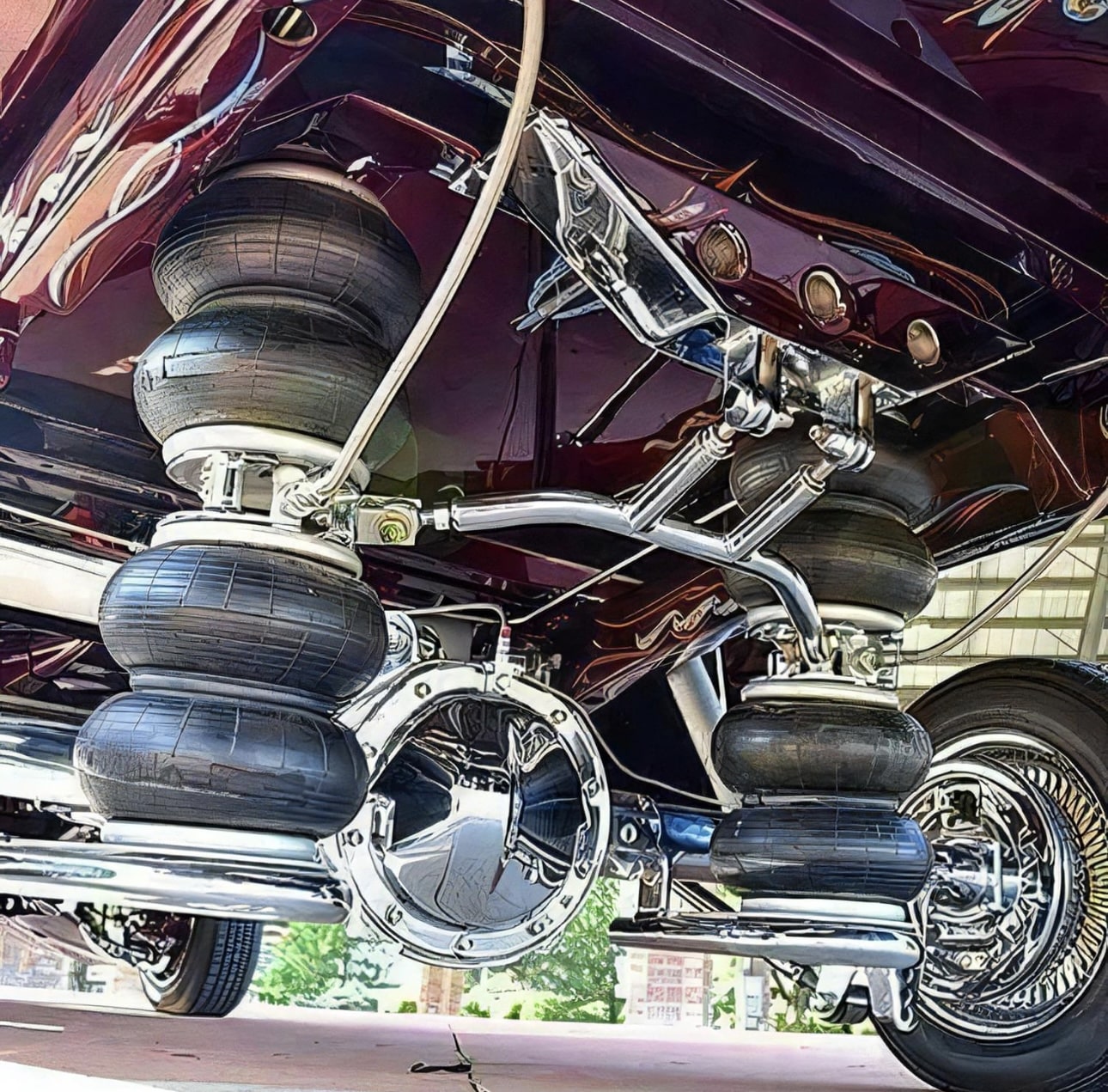

The most popular option is load support, which replaces the bump stop with heavy duty airbags. This kit will lift your camper/motorhome, improve handling and ride quality. It will not make your vehicle go any lower than it already is - for that you need an entirely different kit, which is called "full rear" - and we have a selection available on our website for the most popular vehicles. These load support kit also known as auxiliary suspension or semi-suspension also have a place in the procedure for re-rating the vehicles.

All our load support kits use heavy duty, 6 mm steel brackets that are designed to cope with the loads involved and won't slip, bend or break. Beware of kits with 4 mm brackets - it might not sound like much of a difference but it is: 4 mm brackets are inadequate for heavy vehicles (campers and every motorhome!) and will bend under pressure, affecting the ride quality, damaging airbags and leading to costly repairs.

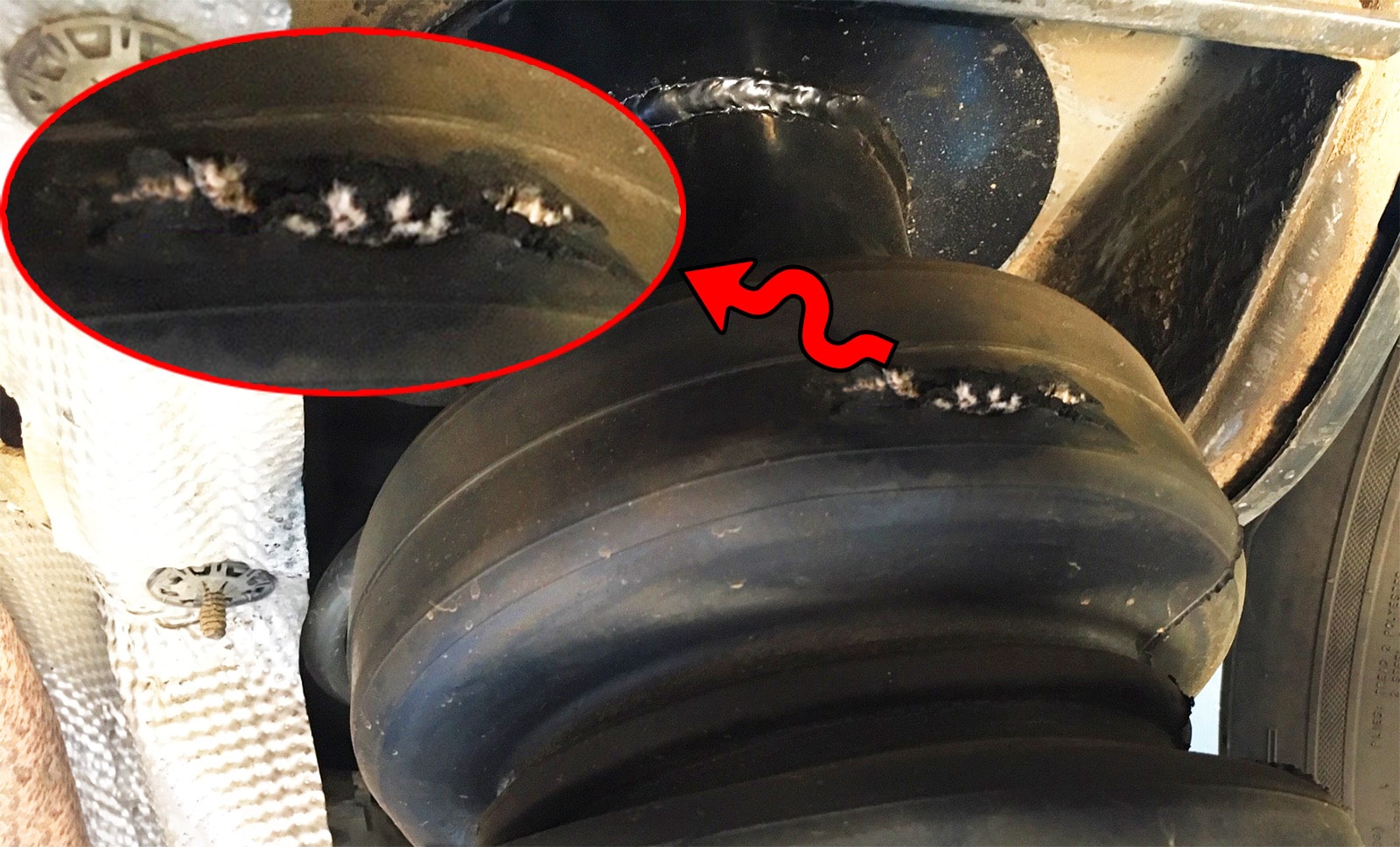

A few years ago, we switched to Boss Air Suspension bags and have never looked back. Boss produces the toughest bags on the market. We've praised them in blog posts in the past and for a very good reason - Boss bags have phenomenal load capacity, more than 1t per side on top of the axle capacity, and they're virtually indestructible. The only way to destroy a Boss bag is by installing it incorrectly, or driving the vehicle with no air pressure in the airbag (same with all bags tbh), which is why its particularly important to check you vehicle if its not used over the winter.

Of course, everything mentioned above means we are charge more for our kits than our competitors and we understand that it's tempting to look elsewhere trying to save money. After all, air suspension is air suspension and all airbags are the same, right? Wrong! Really cheap kits include thin brackets that could cause serious damage to your camper/motorhome and light duty bags that might be OK on an empty van that occasionally carries loads. This is totally unsuitable for campers/motorhomes that are heavy even when empty. Even if the thin brackets will stay in place, the light duty bags won't be able to do much if anything to help your ride quality. We once had a customer who had already spent around £1300 to fit load support that made no difference. We inspected the vehicle and saw the usual combo: a light duty kit with an emergency tyre inflator compressor (designed to be used 1-2 times a year) instead of an air suspension compressor. It took forever to pump air into the bags and that wasn't even the worst news we had to deliver: the kit was the wrong kit for that vehicle. We had to replace the entire kit and on board air system with proper air suspension parts to get the customer what he wanted, what he needed, and what he had already paid for! Remember buy right, buy once.

Rear kit for coil spring campers

If your camper has coil spring on the rear, such as the hugely popular VW Transporter, then our rear kit will replace the existing suspension, meaning you can lift and lower the rear of the vehicle. We supply kits for T25/T3, T4, T5 and T6, as well as Vitos/V-class and Vivaro/Trafic.

Front kit

Although a rear kit can make a huge difference, we get asked about front air suspension a lot. Fiat Ducato front struts are among our best selling products, followed by VW T5/T6 struts. We can supply struts for most vans, including the new VW Crafter and Mercedes Sprinter, Vivaro and Vito's. If your camper/motorhome has struts on the front, we can make air suspension struts for it! They are all made to order using the highest quality OEM spec twin tube shocks - we dont use motorsport type single tube dampers as our customers don't race their vans on circuits, and prioritise comfort and durability.

On board air

"Do I need on board air?" is one of the most frequently asked questions. It depends has to be the answer. A big proportion of our customers simply want to lift up their sagging motorhome and don't need the option to adjust air pressure on the go. For them, basic Schrader valves are a suitable solution. For customers who want to adjust height and pressure on a regular basis, we recommend adding one of our On Board Air (OBA) options. Standard OBA is great value for money and is designed for weekly adjustment. For more frequent adjustment we recommend the higher spec Premium OBA. About 20 years ago only 1:20 customers went for full OBA, however as knowledge has spread about the benefits of actually being able to adjust the suspension (it easily doubles the effectiveness) then that ration is now almost 1:2.

Some of our customers opt to buy a basic kit with Schrader valves and add OBA later, if required, and if you are not sure or want to spread the cost this can be a good way to go. Please note that this does not work on all vehicles. On board air is always required on vehicles with both front and rear air suspension. Tip:- If you have grounding issues of any kind then you DO need OBA.

Any questions? Can't find your vehicle? Call us on 0800 772 0315 or send an email to ENQUIRIES@AIRRIDE.UK