Please note:

Motorhome owners with basic air suspension often call us to ask how to properly operate their air suspension. These notes are about getting started with most of the commonly-available systems. Since they are based upon never having seen your particular motorhome or conversion, they are intended for guidance only. If in any doubt take the vehicle to a motorhome specialist for inspection.

Safety First!

Don not under any circumstances work under a vehicle without adequate levels of support. Never trust any air suspension system to stay inflated whilst you are under it. Unsafe working practices with any suspension can result in very serious injury or death. Air suspension has additional concerns and procedures which must be adhered to - they have additional dangers of injury or death.

The first thing to do before putting air in the system is to carry out a visual inspection of the air bag - particularly if you have just bought a vehicle or it has been standing for a while. If the bag is perished (has small cracks to the rubber) it will need to be replaced. Safe working practice is to replace bags in pairs. The first place to start is the original manufacturer or installer if they still exist. During our time in the air suspension business almost none of the original manufacturers still exist. If you need replacement parts and the manufacturer does not exist please do get in contact.

What is a load support kit?

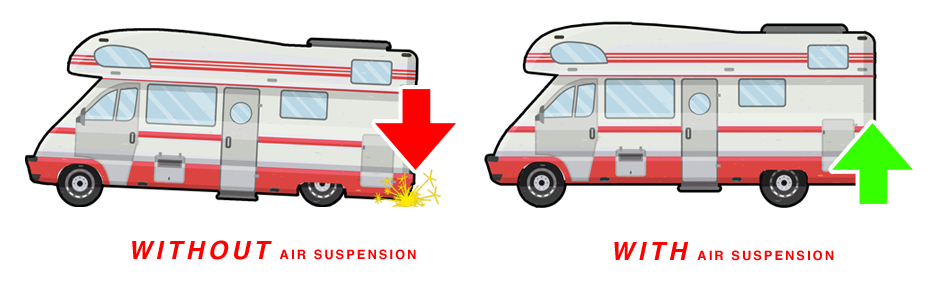

A load support kit is the kind of air suspension you will likely have fitted to your motorhome. They are fitted to improve ride quality, reduce grounding, and lift sagging vehicles.

What is the right air pressure for my suspension?

Each person would probably consider the quality of their air suspension perfect for them at a different pressure. Thus, there is no right or wrong pressure, so long as it is between 20 and 100 PSI. Each vehicle is built and loaded differently, so it makes sense that the correct pressure on each vehicle is different. Most airbags (also called air springs and sometimes bellows) on the market are rated up to around 100 psi. For leaf spring motorhomes it should not be necessary to go to this pressure although it varies from vehicle to vehicle.

How do I know my air works?

To test the system you will ideally need to have or borrow a tyre inflator with a gauge. Most have a side button which will gently lower the pressure, although most people don’t even notice it!

Inflate the vehicle to 20 PSI and notice the height of the vehicle – you can measure at 10 PSI intervals right up to 100 PSI. This will give you an indication of the range the bags work at – initial increases will provide little or no increase in the height of the vehicle. You should then notice that lift occurs in the mid-range, and as you get to the top there is again not much additional lift.

If the hand brake is on, some creaking may occur as it is lifted and dropped – you may also find the handbrake tighter to release. Don’t worry, this is normal!

How do I set the right pressure?

To begin with, leave the vehicle at 100 PSI and go for a drive; ideally on a combination of both bumpy back roads and smoother main roads.

After you have a feel for the vehicle, stop safely and drop the pressure by 10 PSI. Repeat this until you get to 20 PSI (provided you can drop that low without grounding).

We strongly advise taking notes of each pressure and how it feels on both roads and corners. Ask yourself:

- What is the handling like?

- What is the ride quality like?

- What are the load support and stability like?

- Does the motorhome bounce or crash?

After this you will have a good indication of what pressure is needed to drive. The perfect pressure may be different on main roads and back roads and you will probably have to make some sort of compromise. Leave a note in the vehicle of what pressures you decide work best as it can be hard to remember years later, or for a new owner to know (we provide free stickers if you email your name and address.)

As a general rule, most leaf-spring motorhomes would need between 50 and 80 PSI. Coil-spring or torsion-bar (AL-KO) vehicles can be very different. If you’re not sure which kind of spring you have, e-mail us and we’ll ask for some pictures to try and work it out for you.

Be careful!

Please be warned that running the vehicle with no pressure will damage the bags. A minimum of 20 PSI should be retained in the bags at all times - including when stored over the winter. A correctly functioning air suspension system will hold air for years just like a tyre. It should be checked regularly just like a tyre.

Also be aware that all bags (particularly reversible-sleeve bags) should be deflated when the vehicle is jacked clear of the ground or again they could be damaged. Furthermore, this is potentially very dangerous for the user/mechanic. Additional procedures are required when working on air suspension, including when changing wheels.

Set-Up of Basic Motorhome Air Suspension Kit

Important Notes for Motorhome Owners

Many motorhome owners with basic air suspension systems contact us for guidance on how to properly operate their air suspension. This information is intended to provide general guidance for most commonly available systems. Since we haven't inspected your particular motorhome or conversion, these tips are for reference only. If you're ever in doubt, we strongly recommend having your vehicle inspected by a motorhome specialist.

SAFETY FIRST!

Never work under a vehicle without proper support!

Always ensure the vehicle is securely lifted and supported with appropriate jacks and jack stands before working underneath. Under no circumstances should you trust an air suspension system to stay inflated while you're working underneath the vehicle. Unsafe practices with any suspension system can result in severe injury or even death. Air suspension systems come with additional safety risks and require extra caution during installation and maintenance. Always follow safe working practices.

Before inflating the system, perform a visual inspection of the airbag, especially if you've recently purchased the vehicle or if it has been stationary for a while. If you notice any signs of wear, such as small cracks in the rubber, the airbag will need to be replaced. As a best practice, replace air springs in pairs for consistent performance. If you're unable to find parts from the original manufacturer or installer, don't hesitate to get in touch with us for assistance.

What is a Load Support Kit?

A load support kit is typically the type of air suspension installed on most motorhomes. Its primary purpose is to improve ride quality, prevent bottoming out (grounding), and reduce sagging, particularly when carrying heavy loads. These kits help ensure that your motorhome remains level, providing a smoother and safer driving experience.

What is the Correct Air Pressure for My Suspension?

The ideal air pressure for your motorhome’s air suspension can vary depending on your specific vehicle and how it's loaded. There is no one-size-fits-all answer. However, air pressure should generally be kept between 20 and 100 PSI. Most air springs (also known as airbags or bellows) are rated to handle pressures up to around 100 PSI, though most motorhomes won’t need to reach this pressure. For leaf-spring motorhomes, pressures lower than this are typically sufficient, but the optimal pressure for your vehicle will depend on your specific setup.

How to Test Your Air Suspension System

To ensure the air suspension system is functioning correctly, you’ll need a tyre inflator with a gauge (if you don’t have one, they can be borrowed or purchased). Most inflators feature a side button that allows you to gradually adjust the pressure, which is useful for testing.

- Start at 20 PSI: Inflate the air suspension system to 20 PSI and observe how the vehicle height changes. You can increase the pressure in 10 PSI increments, up to 100 PSI, and measure the change in height at each stage.

- Observe Lift Characteristics: At lower pressures, there will likely be little to no change in the height of the vehicle. However, once you reach the mid-range pressures (around 40-60 PSI), you should notice a more significant increase in lift. As you approach higher pressures, additional lift will become less noticeable.

- Handbrake Creaking: When inflating or deflating, you might hear some creaking or find the handbrake becomes slightly more difficult to release. This is completely normal and should not be a cause for concern.

How to Set the Right Pressure for Your Vehicle

To find the optimal air pressure, start by inflating your suspension to 100 PSI and take the vehicle for a test drive. Aim to drive on a variety of road surfaces, including bumpy back roads and smoother main roads.

- Take Notes: During your test drive, pay attention to how the vehicle handles, the ride quality, and the load support at different pressures.

- Adjust Pressure in Increments: After driving, reduce the air pressure by 10 PSI increments and repeat the test drive. Continue until you reach a pressure where the vehicle is handling well without bottoming out (typically no lower than 20 PSI).

- Evaluate Ride Quality: Ask yourself these questions as you test different pressures:

- How does the vehicle handle on curves and uneven terrain?

- Is the ride smooth, or does it feel bouncy or harsh?

- Does the air suspension provide adequate load support and stability?

- Does the vehicle bottom out or crash over bumps?

Record the pressure at which the vehicle feels most stable and comfortable, and keep this note in the vehicle for future reference. You may find that the ideal pressure varies depending on the type of roads you're driving on. It’s also helpful for future owners, and we can provide free stickers with the pressure settings if needed.

As a general guide, most leaf-spring motorhomes typically require 50 to 80 PSI for optimal performance. Vehicles with coil-spring or torsion-bar (e.g., AL-KO) suspension may require different pressures. If you're unsure about your suspension type, feel free to contact us with pictures of your setup, and we'll help determine the correct pressure range.

Important Safety Considerations

- Never operate the air suspension system without a minimum of 20 PSI in the bags. Running the system at too low a pressure can damage the airbags. This is particularly important when the motorhome is in storage, especially during the winter months.

- Deflate the airbags when jacking up the vehicle. If the vehicle is raised off the ground for any reason (such as changing a tyre), make sure the airbags are fully deflated to prevent damage. This is a crucial safety measure for both you and the mechanic working on the vehicle.

- Regular Checks: A well-maintained air suspension system should hold air for extended periods, much like the tyres on your vehicle. However, it’s still essential to check the air pressure regularly to ensure everything is functioning properly.

By following these steps and tips, you’ll be able to maintain your motorhome’s air suspension system and enjoy a smoother, more controlled ride. Always prioritize safety, and if you ever have questions or concerns, don’t hesitate to reach out to us for expert advice.