Welcome to the AirRide Guide to compressors. Watch the video or read the information below (or both!) to find out everything you need to know!

Do I need an air compressor?

Air suspension needs air to work. For the most basic motorhome and van systems this does not necessarily have to be on-board the vehicle and they are sometimes inflated from a normal tyre inflator at a workshop or petrol station using a Schrader valve (the tyre valve that all vehicles have).

However, most air suspension systems will include On-Board Air (OBA) and these vehicles will all contain a compressor, which generates an air supply and fills the air tank. The reason it's called On-Board Air is because the air is generated on-board, and not from an external source; the compressor effectively replaces the Schrader valves but of course does an astronomically better job!

All air suspension vehicles, including motorhomes, will get the very best from the system when used in conjunction with an OBA system (otherwise known as air control or management).

What is a compressor?

The compressor is basically a small air pump, usually powered from the vehicle’s 12v electrical supply. The compressor’s motor turns and pumps air into a tank, which stores a reservoir of pressurised air for immediate use.

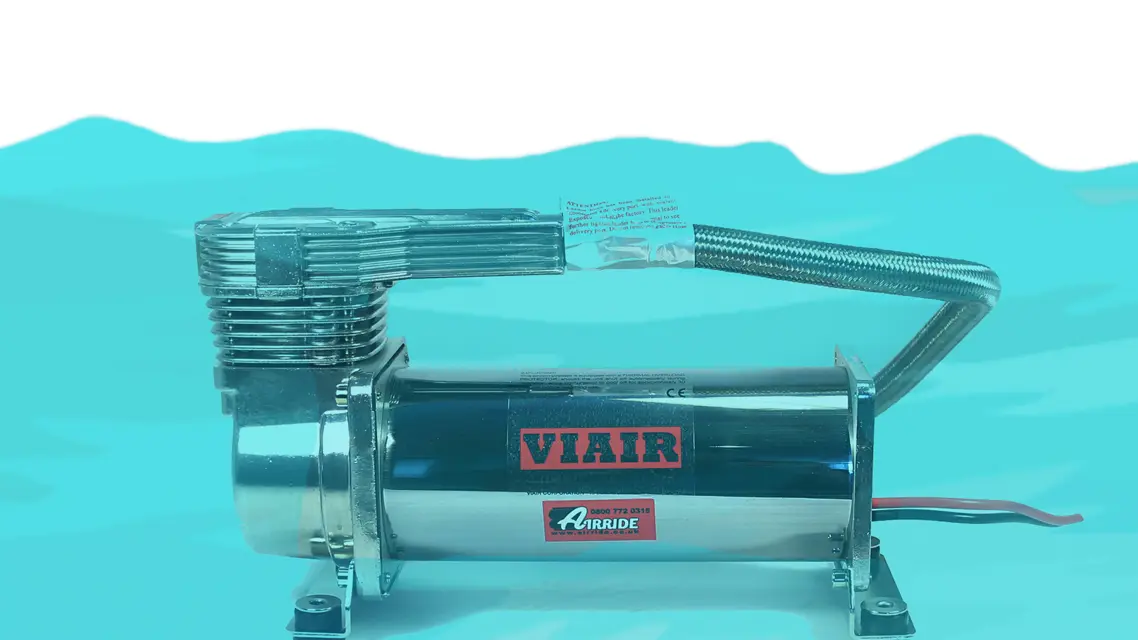

Our air compressors are high-quality, extremely reliable, and come with a stainless leader hose pre-fitted and pre-tested – these never leak (unlike hoses that aren’t pre-fitted that can be very unreliable) and draw a consistent electrical load. They are also light and quiet.

Viair is the dominant supplier because they offer quality and represent good value for money, and it is their compressors that we mainly supply. In almost 20 years we have never had a compressor returned to us.

The Viair 485C compressor

The Viair 100C compressor

How do compressors work?

Most compressors use your vehicle’s electrical system to turn a crank and piston in the head of the compressor which in turn pumps air into your air tank. This takes place within the head of the cylinder (see diagram above). This technology means a compressor will not overheat at the same time as maximising air flow and air compression.

Viair, our suppliers, are the leading manufacturers of air compressors and utilise the most modern technology.

Is one compressor enough?

Top-spec air installations will often use two compressors to ensure air tanks are filled more quickly and to reduce the load on each compressor. This is called system redundancy.

Having system redundancy ensures you always have enough air to make your suspension system work (i.e. you may also have some extra ‘redundant’ air that you don’t need.) This may also extend the life expectancy of your compressors because it’s not always operating at, or close to, maximum capacity (it’s basically having an easier life.)

While having more than one air compressor is ideal, your air suspension can still run with just one.

What is duty cycle?

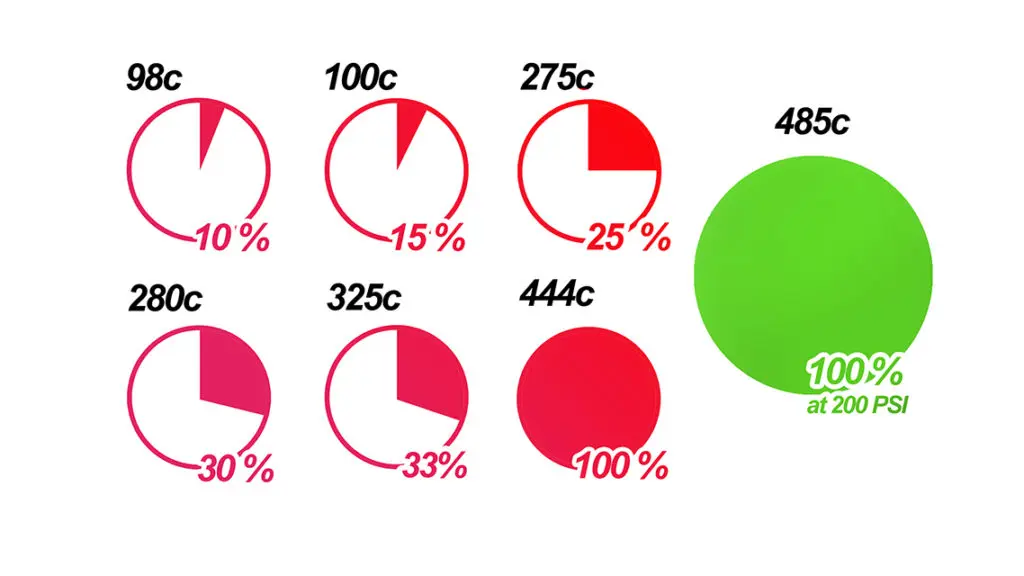

Duty cycle is the proportion of a ten-minute period that the compressor can run before needing to be rested to cool and recover. Exceeding the duty cycle will cause rapid failure of the compressor.

When choosing a compressor, it is extremely important to pay attention to duty cycle. For instance, while cheaper Firestone units are good compressors, they are only rated at 7% duty cycle (they can be used for 42 seconds and then should be rested for the remaining part of the ten-minute period). This is obviously far from ideal but many suppliers still insist on using them.

All AirRide’s compressors that are supplied with full kits are rated at 100% duty cycle at very high pressures (many of our compressors can run at 100% duty cycle at 100 PSI or even 200 PSI (pounds per square inch) – the more pressure generated, the higher the PSI). An 100% duty cycle means the compressor can be used 100% of the time.

Why do compressors fail?

The main cause of compressor failure is customers or suppliers simply choosing the wrong item for the job. Cheap kits often include compressors with very low duty cycles (which remarkably can often be less than 10%). These simply won’t function for very long in an automotive system. Others are susceptible to damage from moisture or dirt (these would have a low IP rating) or require the client to fit a hose to the cylinder head to install it on the system. Since this is the most likely place for a leak this should be factory-fitted and tested to avoid issues for the client. All our compressors include fitted leader hoses.

Feel free to get in touch if you’re concerned about choosing the right compressor for your vehicle.

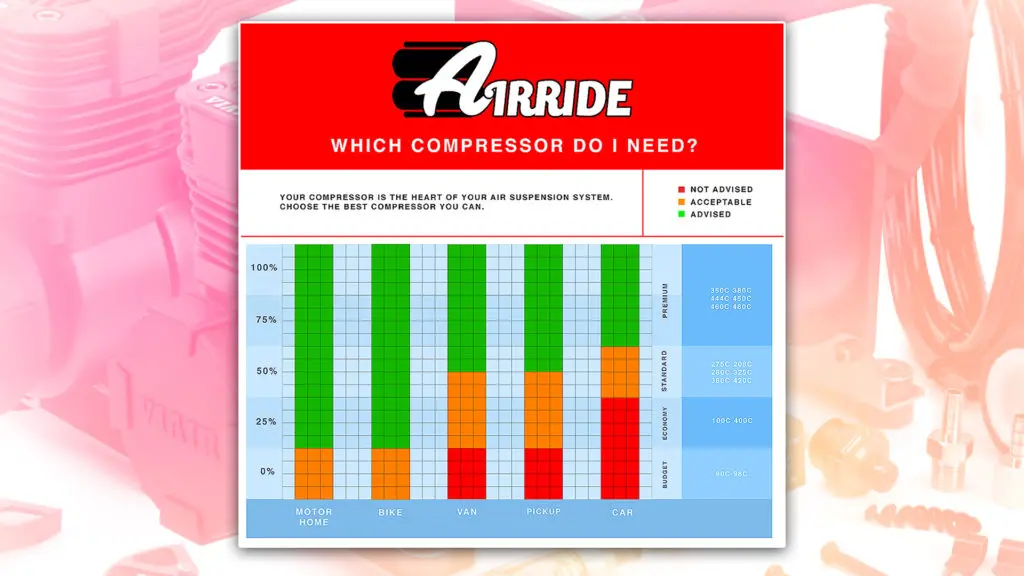

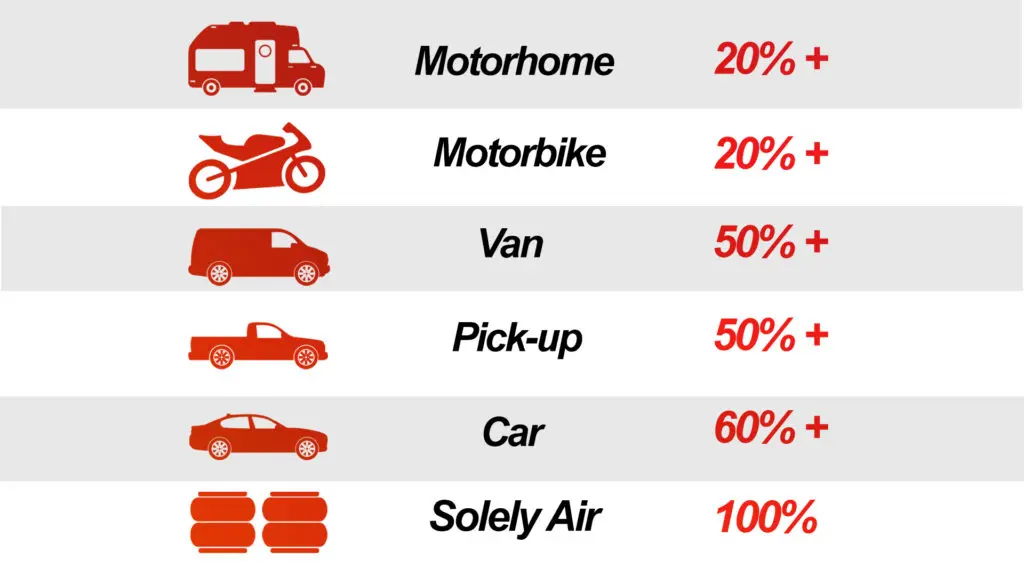

Recommended minimum duty cycles for different vehicles.

The different duty cycles of some of the compressors we sell.

What is an IP rating?

An IP rating measures the level of water and dust protection on a compressor. It’s important to buy a compressor with a high IP rating (ideally IP67 or higher) to ensure the longevity of the compressor. All Viair’s high-end compressors are IP67. This offers about the same protection as an iPhone 8 and means the compressor could be immersed in up to 1 metre of water for up to 30 minutes without harm. A compressor with a high IP rating can also be located under the vehicle if necessary.

Many compressors are not IP-rated at all so be wary of these!

Why are pressure switches important?

The pressure switch is a vital safety device and its correct placement and reliable function is essential to the safety of the system.

If the pressure switch is fitted directly to the cylinder head of the compressor, it will fail. This can be the cause of failure for cheaper compressors, as when the switch fails the compressor will simply run until it dies. This is why it’s important to get a compressor with a duty cycle of 100% – so even if the pressure switch fails, your compressor won’t.

What does an air tank do?

An air tank provides instant air when needed, as opposed to waiting for your compressor to supply it. This way, the air is always available at the touch of a button; you can adjust the height of your vehicle to overcome any obstacle you may face.

You can have an air suspension system with a compressor and no air tank but this will make your system slower.

What is a plastic tyre inflator?

These small, emergency tyre inflation compressors are not suspension compressors. They work a few times and are great in an emergency but are no substitute for a full air suspension compressor. Air suspension compressors are usually distinguished by an almost-total lack of plastic and will be aluminium due to the heat they generate.

A compressor with an IP67 rating can last in up to one metre of water for as long as 30 minutes (we don't recommend testing this though!)

Some compressors, such as the 485C, can come in dual packs to reduce the risk of failure.

AirRide compressor choice chart

The numbers on the left of the y-axis indicate duty cycle, while the numbers on the right of the y-axis represent the models of Viair compressor that we sell. Ideally, we always advise choosing at least a 444C or above (i.e. 450C, 460C etc.). Make sure to always check the duty cycle before buying a compressor though.

What to look for when choosing a compressor

- Maximum pressure (this goes up to 200 PSI)

- Duty cycle (a 100% duty cycle is undoubtedly best)

- An all-metal construction

- Braided leader hoses (so much heat is generated by an air suspension compressor that a heat-and-vibration-resistant hose is required from head to tank.)

- A non-return valve (to prevent pressure from the air tank leaking back into the compressor the line must have a non-return valve.)

- OEM (Original Equipment Manufacturer) replacement (most compressors are have a better duty cycle and are higher quality than the OEM’s and are often supplied as replacements.)

If you are still unsure which compressor to choose, please feel free to call or e-mail us to talk to an AirRide adviser. However, a general rule of thumb is the higher the duty cycle and pressure, the better, even if you don’t use it to full capacity.